This post is sponsored by GE.

When skull implant patients like Chris Cahill are rushed to the hospital, they usually don’t remember getting there.

They’ve typically sustained severe head trauma from a fall or car crash and are in critical condition — or, in Cahill’s case, a 2-month coma after an accident left him with life-threatening swelling in his brain and an infection in his skull.

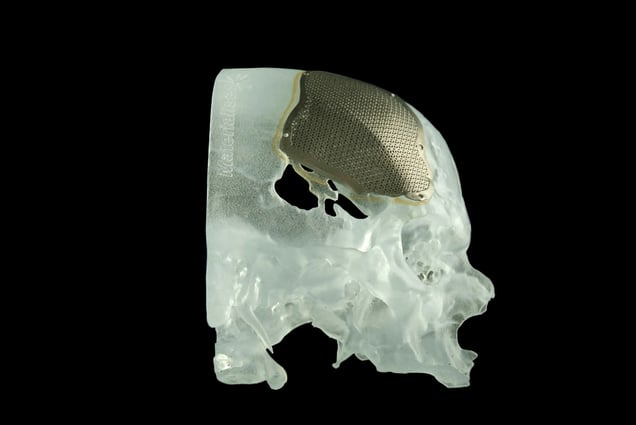

Cahill’s condition was so dire that his doctors had to remove part of his skull, leaving him with a visible defect, part of his brain unprotected, and no healthy skull bone to perform reconstructive surgery.

But, they did have one option: A cutting-edge procedure that virtually didn’t exist a decade ago, which would leave Cahill looking “exactly the same” as before the accident.

His doctors relied on a kind of 3D printing tech called additive manufacturing to create a custom-fit skull implant — the same tech, coincidentally, that jet engineers now use to condense 855 airplane parts into just 12. And, if you thought 3D printing was only good for making toy-sized replicas of your loved-ones, you might want to sit down for this one…

Welcome to the Build-A-Skull Workshop

If Cahill had this procedure done 10 years ago, chances are he wouldn’t have looked “exactly the same.” In the ballpark maybe, but that’s not exactly a win when it comes to facial reconstruction.

These types of skull and facial reconstructive surgeries would’ve taken doctors like Cahill’s hours of ‘guess-and-check’ work using hundreds of out-of-the-box plates and screws.

“Just guessing” — not the phrase you want to use when you’re talking about rebuilding someone’s face.

And, even when you did find parts that were close, it was like trying to complete a puzzle when none of the pieces quite fit: “we never had the correct, perfect shape,” Dr. Laurent Lantieri, the plastic surgeon who performed the first full face transplant, recalls.

Now, when Lantieri enters the operating room to perform a reconstructive procedure, he’s equipped with a 3D printed, custom-fit patch kit for his patients.

It’s essentially a “Build-A-Skull workshop” for skull and facial reconstruction: Instead of digging through hundreds of parts, OR nurses already have all the necessary components packaged in order of use, and Lantieri knows “exactly what we have and where it goes.”

According to him, they “just have to open the box.” And it’s all thanks to additive manufacturing — industrial-grade 3D printing that allows a machine to manufacture complex, Escher-like parts with precision and speed never before possible.

So, how do you “3D print” something, exactly?

In general, 3D printing is a process where a physical object is created from a digital blueprint of something that’s “sliced” into thin horizontal layers and uploaded to a printer.

But, unlike “desktop 3D printers” (which push melted material out layer-by-layer like a hot glue gun) typically used for small-scale plastic prototypes, additive manufacturing can create complex, fully-functional metal parts (like Lantieri’s skull implants) up to 1m in diameter.

First, Lantieri sends a 3D CAT scan of his patient’s face out to an additive manufacturing firm for modeling. Using reference points from features on the undamaged side of the skull, engineers produce a complete, 3D model of the patient’s skull pre-accident.

Then, the firm uses the model to 3D print an implant that fits like a glove (or a hat, rather), pairs it with custom screws and tools, and delivers them to a hospital in a single, specialized kit.

Here’s how the actual ‘printing’ goes down:

- Additive machines spread a thin layer of metal dust on a platform.

- A laser melts the dust according to the first “slice” of the design.

- The platform is lowered, more powder is spread on top, the laser does its business.

- Rinse and repeat.

- When all the layers are complete, the entire object is pulled from the powder in a single piece.

The implications are massive

Literally. Last November, the head of GE Additive, Mohammad Ehteshami, unveiled a beta version of the world’s largest powder bed 3D printer — a machine roughly the height of a basketball hoop.

From an engineering perspective, the impact is even larger.

Additive allows manufacturers to make stronger parts with less material than traditional manufacturing methods like “casting” (where metal is poured into a mold, cooled, then removed). And, compared to a milling machine (which carves parts from a solid piece of metal), there’s no waste — any un-melted powder can be used in the next print.

These machines can also print with a vast range of “ink,” from biocompatible polymers (stuff that your body won’t have an adverse reaction to) for implants, to metals used in jet engines.

Case in point: the GE Catalyst Turboprop engine. One part of GE Aviation’s first 3D printed commercial aircraft engine, which passed its first test last Christmas, is now made from just 12 components (down from 855 components in its traditionally-manufactured predecessor).

It’s also 100 pounds lighter, 20% more fuel efficient, and 10% more powerful. In short, it’s “an engineer’s dream.”

So, how did this all come to be?

A man, a nozzle, and a dream

Just over a decade ago, Ehteshami (then-Head of Engineering for GE Aviation) and his team were working on a cutting-edge engine poised to be far more fuel efficient than its predecessors. There was only one problem: The fuel nozzle it relied on was insanely complex.

It required over 20 parts that had to be individually assembled together — a feat that proved impossible with traditional methods. “We tried to cast it eight times, and we failed every time,” Ehteshami told GE Reports.

Luckily, Ehteshami knew a guy.

Back then, entrepreneur Greg Morris owned a boutique 3D printing company in Cincinnati called Morris Technologies that was pioneering a new technology called “additive.”

GE Aviation had worked with Morris on one-off projects and prototypes in the past, but this was different: The product would need to be printed on a mass-production scale, something no one had ever accomplished in aviation — and, if Morris succeeded, it could change the way jet engines were made forever.

Ehteshami “swore Morris to secrecy” and sent him the computer file for the nozzle tip. Days later, it was printed. The new design combined all 20 parts into one component that was 5 times stronger, yet weighed 25% less than an ordinary nozzle.

“I remember that day like today,” Ehteshami mused. “I was excited but also disturbed. I knew that we found a solution, but I also saw that this technology could eliminate what we’ve done for years and years.”

“Oh my God,” he recalled thinking at the time, “if I don’t start moving, somebody else will.”

Too good for its own good

The tech was so threatening to GE’s business model that Ehteshami feared GE would shut down their renegade operation.

After GE Aviation acquired Morris Technology in 2012, they moved a few machines to a drab building away from the main campus and started quietly experimenting…

The results were undeniable. By 2016, GE had expanded its additive portfolio and dropped over $1B on majority stakes in two of the world’s largest industrial 3D printer manufacturers.

That same year, in his letter to shareholders, former GE CEO Jeff Immelt pegged the potential additive manufacturing market at $75B, projecting GE would build an additive business with $1B in revenue by 2020. Now, they’re building this billion-dollar business in old steel towns like Cincinnati and Pittsburgh — the very cities it’s most poised to disrupt.

From steel towns to titanium aluminide towns

GE’s Additive Training Center sits just outside of Cincinnati, in the small town of West Chester, Ohio, population: 61k (of which GE Aviation employs about 3.5%).

Inside the bright, 130k square-foot facility sit nearly 70 industrial additive printers, producing a steady, white-noise hum; compared to the ear-splitting grinding of a traditional machine shop, the ATC is less noisy, more sterile.

An hour away, at GE’s Customer Experience Center in Pittsburgh, 50 engineers clad a strange mix of steel-toed boots and Kubrick-esque protective suits work intently at their million-dollar sandboxes, producing state-of-the-art components 100 microns at a time (that’s less than the thickness of a human hair).

These steel towns are rising again — this time with a quiet confidence. It seems the next manufacturing revolution will come, not with a bang, but a whisper.