By 2050, the world’s population will increase by 2.2B and 68% will live in cities, up from 55% now.

That’s a problem for food, which, unlike people, is staying still. In the US, for example, ~100% of lettuce grows in California and Arizona. The result: distance, time, and distribution account for 20%-35% of produce costs.

This imbalance is particularly notable in China, where rapid urbanization means the country now has 21% of the world’s population but just 9% of the arable land.

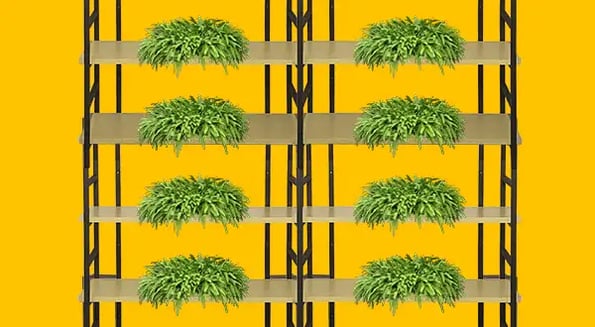

The solution: Build farms up

The next generation of farms are indoors and vertical. “Vertical farms” work like parking garages.

Many don’t use soil; they use materials and sensors that mimic natural environments.

Because they can operate 24/7 and recycle water, the efficiency is f*cking ridiculous: 350x the traditional farm harvest with just 1% of the water.

Midway through this year, indoor farming VC investments were already up 403.4% YoY to $2.7B.

Where’s this happening?

Globally. Major projects can be found in:

- Newark, where AeroFarms has a 70k-square-foot facility growing ~2m pounds of produce annually.

- Abu Dhabi, where the government is offering $150m in incentives for vertical farmers to come build.

- China, where plans are in place for a 51-story office tower doubling as a vertical farm that’ll produce enough crops to feed 40k people each year.

Sounds great. What’s the catch?

Economics, as always

It’s not cheap to build a high-tech super-farm, and it doesn’t make sense to grow every plant in one. One Cornell professor calculated a loaf of bread made from indoor-grown wheat would cost $11.

Costs will likely drop over time. At the same time, innovation will rise.

In 2012, ~60% of traditional farmers were older than 55. Last year, 70% of vertical farmers were younger than 40.

That’s not to say that older folks can’t innovate, but that younger folks are bringing some new ideas to a ~10k-year-old industry.

(Have any thoughts about vertical farms? Let us know here.)