Via Getty Images

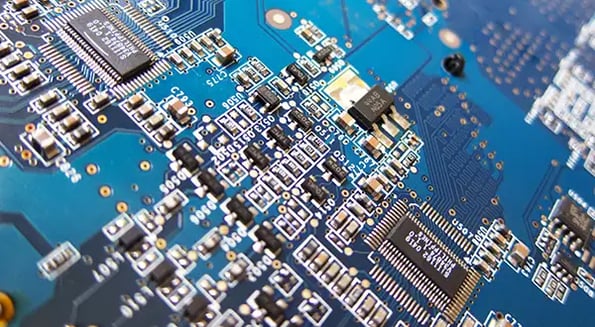

At a basic level, there are a few ways to make money in the world of microchips:

- Producer: Design microchips yourself and sell them to customers

- Foundry: Manufacture chips according to customers’ designs

Intel built an empire doing the former, continuously outpacing rivals with leading-edge designs.

Then, a combination of factors knocked it off this path:

- Apple, one of Intel’s biggest customers, began designing its own chips, and enlisted TSMC (Taiwan Semiconductor Manufacturing Company) to manufacture them

- Intel experienced delays in its top chip launches in 2015 and 2017

- Other companies followed Apple’s lead and began designing their own chips

Fast forward to today, and 90%+ of state-of-the-art chips are made by TSMC, with the rest made by Samsung.

Intel wants to be a foundry, too…

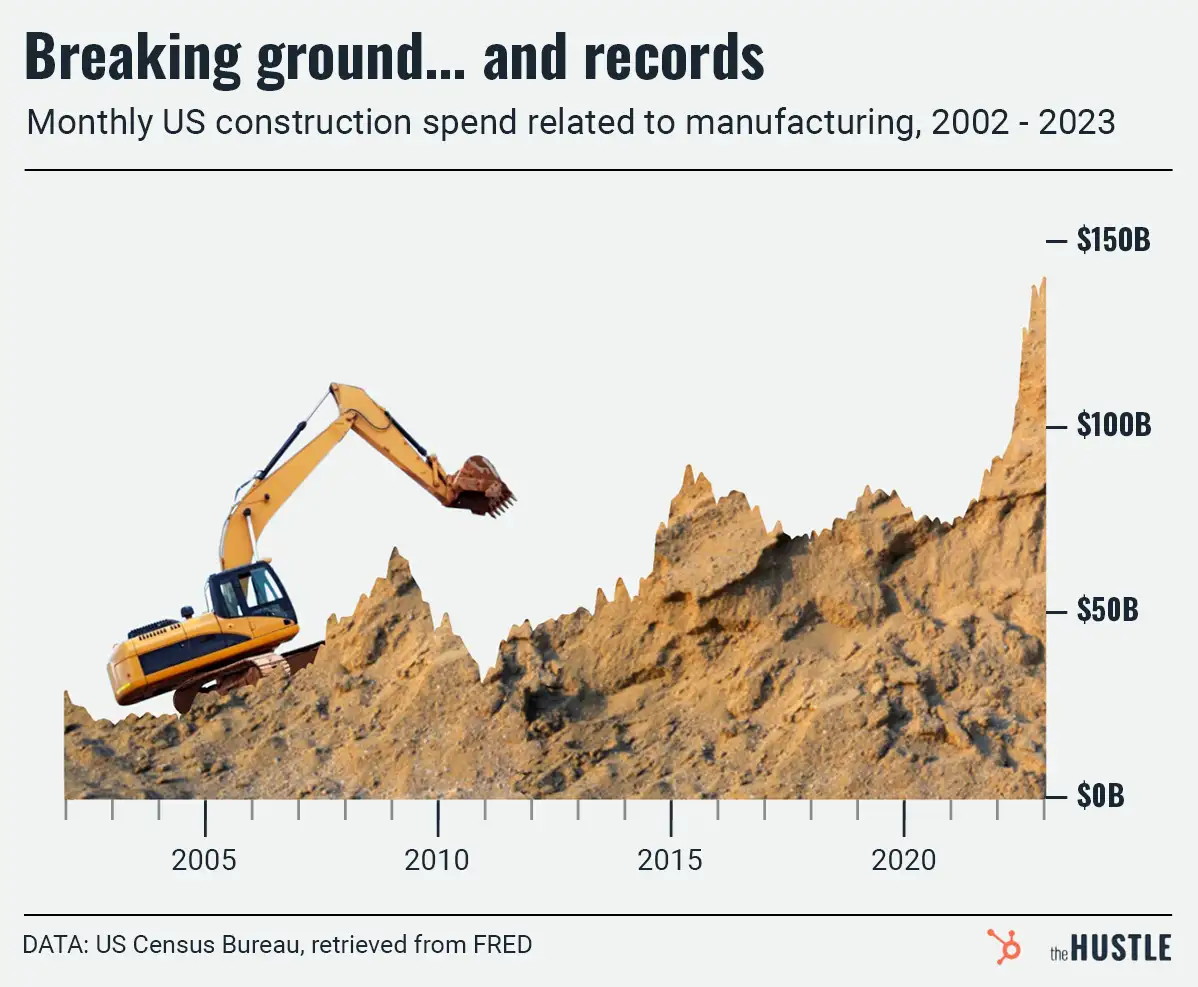

… and they’re willing to pony up the cash to do so. The firm just dropped $20B on 2 new fabs (fabrication plants).

The foundry strategy isn’t without challenges. Manufacturing chips has traditionally had low margins and requires massive scale to be successful.

But once a firm reaches that scale (like TSMC), it creates a virtuous cycle:

- More sales opportunities help perfect the manufacturing process

- More customers lead to faster innovation

It will take time to tell if it’s working

Intel’s fabs will take ~2 years to build, and experts believe it will take 3-5 years to gauge whether the strategy will work.

Notably, TSMC is an outlier, and its margins are boosted by government subsidies that are much higher than the US’s. Experts are still optimistic: The US needs computer chips, and global supply chain issues are proving it pays to have them domestically.

If Intel can be the one to supply them, it may just return to its glory days.